Portland Made: Product Innovator, Sam Pardue of Indow

Monday, April 20, 2015

Product Innovator, Sam Pardue of Indow

So far we have featured, Portland Razor Company, Walnut Studiolo, Caravan Pacific, Made by Mabry, and Togetherfarm. All of these products express values of high design and high quality. Where the intersection of art and craft meet everyday objects. And these locally grown companies are experiencing incredible growth, as the demand for high quality American Made goods continues to increase worldwide.

Portland Makers are showing the nation, and the world, that hard work, passion and the production of real, handmade goods is still an option for success in an economy obsessed with big money tech startups.

This week, Portland Made contributing writer, Peggy Acott, talks with Sam Pardue of Indow, an innovative sustainable window insert company.

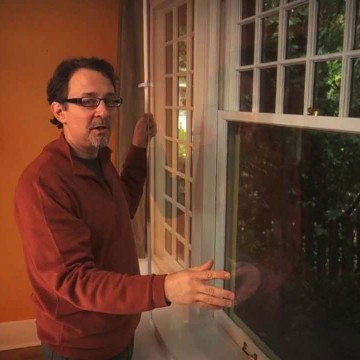

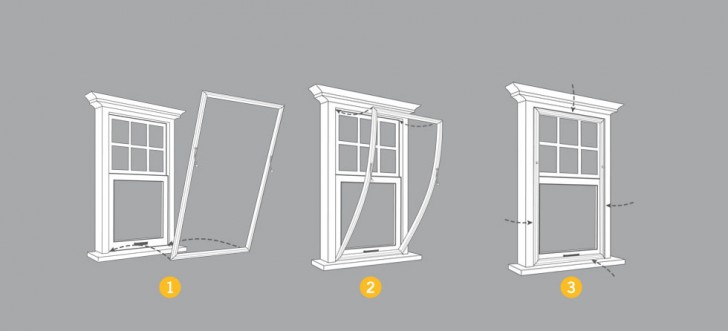

Important inventions are often the result of someone simply trying to solve a problem. This was the case with Sam Pardue. He was living in a house built in 1906, with beautiful wood-framed windows – that unfortunately leaked like sieves. He didn’t want to replace them with vinyl windows for aesthetic reasons, but having wood replacement windows built was cost-prohibitive. And he liked the original wavy glass panes. He experimented with different possible solutions; but it wasn’t until he opened his refrigerator one day and really noticed the gasket that runs around the edge of the door to seal in the cold that the idea struck him: Could he somehow manufacture an acrylic window insert that was rimmed with a similar “gasket” containing internal springs to hold it tightly in place?

This was the beginning of Indow.

That was in 2009. A lot of experimenting and prototyping followed. A huge challenge was the fact that in older houses, windows are rarely “square,” due to the building settling and shifting over time, and that no two windows are the same. Differences between the top and bottom of a window as little as an eighth of an inch would render the inserts ineffective. The answer was to develop a proprietary laser measuring system that involved creating a complicated software program – to ensure the accuracy of complex measurements. (Of the thousands of Indow inserts installed to date in the United States, Pardue says “only a handful” have had to be replaced due to inaccurate measurement.)

In 2010 he went public with beta testing in Portland. It proved to be a steep but effective learning curve; finding the “real problems” that arose resulted in finding answers more quickly. “Being in business is what forced us to solve problems and get the necessary experience,” Pardue explains.

For the next year Indow worked solely with local residential clients; a story in The Oregonian brought them wider attention and gave them the launch into more regional – and by 2012, national – exposure. They were able to eventually set up a network of dealers to help extend their reach and enable Indow to serve commercial clients as well as residential.

All of the materials that go into the production of Indow inserts are U.S. sourced, and every window is handmade. There are now seven different grades of window inserts in production, designed to filter varying amounts of light and noise (the Indow offices are directly adjacent to a railroad track; with the sound dampening inserts, we never barely noticed the freight trains passing right beneath the windows).

“Portland is a great cradle” for Indow, because of the number of older homes their owners want to upgrade yet preserve. Also, its urban-growth boundary is resulting in a developing urban core, where residents can especially benefit from the noise-moderating acoustic inserts. Pardue sees the production of Indow as addressing all these needs, as well as being in alignment with his personal environmental ethos around energy conservation and climate change.

Pardue’s hope for the future is to be able to reach an international market, where there is abundance of old buildings and the desire to preserve them, while making the built environment more energy efficient.

Watch the video from Indow's website to see how Pardue's window inserts work:

Call 503-284-2260 or email [email protected] today to find out how you can integrate Indow into your project. Supporting local companies keeps dollars flowing through our communities and makes our economy strong. Tune in next week as we transition into features about Makers in Portland's rapidly growing food products industry.

____________

Kelley Roy is the founder of ADX, a 14,000 square foot Makerspace where artists and designers work along side each other to prototype and launch new product lines. ADX is also open to the general public and teaches people of all ages how to make. And if you don't want to do it yourself, you can hire them to do it for you. For more information check out adxportland.com.

Portland Made is a digital storytelling platform and advocacy center for Portland's Maker Movement. We do 2 features a month on Portland Makers; connect makers with more local, national and international markets; connect makers with local professional and manufacturing resources; advocate for makers with politicians at all levels of government; work with PSU on an annual survey that captures the economic power of the Maker Movement; help makers find real estate; and promote Portland makers with local and national media.

Related Articles

- Portland Made: Lamp Designer Shannon Guirl

- Portland Made: Straight Razor Maker Scott Miyako

- Portland Made: Woodworker Josh Mabry

- Portland Made: Working Together ADX + Togetherfarm

Delivered Free Every

Delivered Free Every

Follow us on Pinterest Google + Facebook Twitter See It Read It